In Fall 2024 I was fortunate to attend the 9th ASEAN Summit Textile Symposium in Vientiane, Laos. Visiting the Traditional Lao Silk Residence which opened October 23rd was a special highlight due to the age and variety of textiles exhibited all in one location.

Prior visits to Laos meant arranging visits to private museums held by individuals or organizations to see historical textiles created more than 100 years ago. Without doubt I will leave some families or organizations out of my examples but the Lao Textile Museum offered by the Sisane family, the Phaeng Mai Gallery & Khang Fashion Designs offered by the Nanthavongdouangsy family offer books, weaving lessons and history. NGO’s and Lao Woman Organizations such as Ock Pop Tock provide living demonstrations, teaching and shop access. Mulberries, the manifestation of Madame Kommaly Chanthavongk’s vision of connecting the Sam Neau silk farmers to the world markets is represented beautiful by a newly opened teaching center, shop and family museum showing the connection after war and the textiles brought out by families through this war. Finally TAEC or Tradition Arts & Ethnology Centre takes on the presentation of ethnic groups and defending their rights to their artform.

As an American weaver I would be remiss if I did not mention Lao Textiles Gallery owned by American Carol Cassidy who has worked within this inspiring cultural over 35 years and her contributions to sharing knowledge about Lao weaving and Dr. Linda McIntosh, writer and textile curator, co-owner of Galeri Asiama and co-organizer of the 9th Asean Textile Symposium. Both Americans, in their own way, have contributed greatly to Lao textile scholarship. All above are excellent resources to learn but a National public museum honoring textiles is missing.

In answer to these private and worthy efforts of talented individuals the Lao Handicraft Organization and the Lao Government Ministries renovated the Hor Kham Residence, which is adjacent to the Presidential Palace and they organized and displayed a collection of over 100 textiles, some over 300 years old for public access. To quote Ms. Souvita Praseuth, President of the Lao Handicraft Association: “We aim to celebrate the ethnic diversity and cultural richness of Lao textiles, focusing on heritage preservation, innovation, and the global recognition of Lao handicrafts.”

It is a massive job well done. We were only allowed about two hours in the exhibit on the last day of the conference. Sadly, I had not realized the exhibit existed prior or I would have spent much more time visiting the site. It will remain open thru February 2025 and hopefully will provide a working model for future textile permanent exhibits. Little is written so far about the exhibit but a search on the internet on “Traditional Lao Silk Residence” will provide additional details. It was worth the trip for this exhibit.

As a weaver I captured images from this exhibit as we were allowed to freely photograph the pieces. As another visitor, Mr. Thomas Murray said, “I want to come back and fully photograph each piece and the label to construct a catalogue of this worthy exhibit”. As each of these pieces were shared from private family collections and will return to the owners a catalogue will surely be welcomed by the textile world and honor the makers. Additionally, it is possible that different family pieces will be rotated into the exhibit and others retired. An exhibit worthy of multiple visits if your travels permit it.

Below are visual examples of the simple loom variations weavers used to create these masterpieces and many photos of these historic textiles.

A word about the looms, I have been visiting, teaching and writing about these regional looms over 25 years and continued to be fascinated by the relationship between the weavers, the loom, the pattern devices and the warp. It is a symbiotic relationship between objects and humans.

The Lao Khao Tam Huuk – is the heart of the pattern brocade that is stored. These photos & videos briefly show the use of the pattern device. It is used for continuous or discontinuous supplementary weft.

after inserting inlay and tie down weft

discontinuous weft

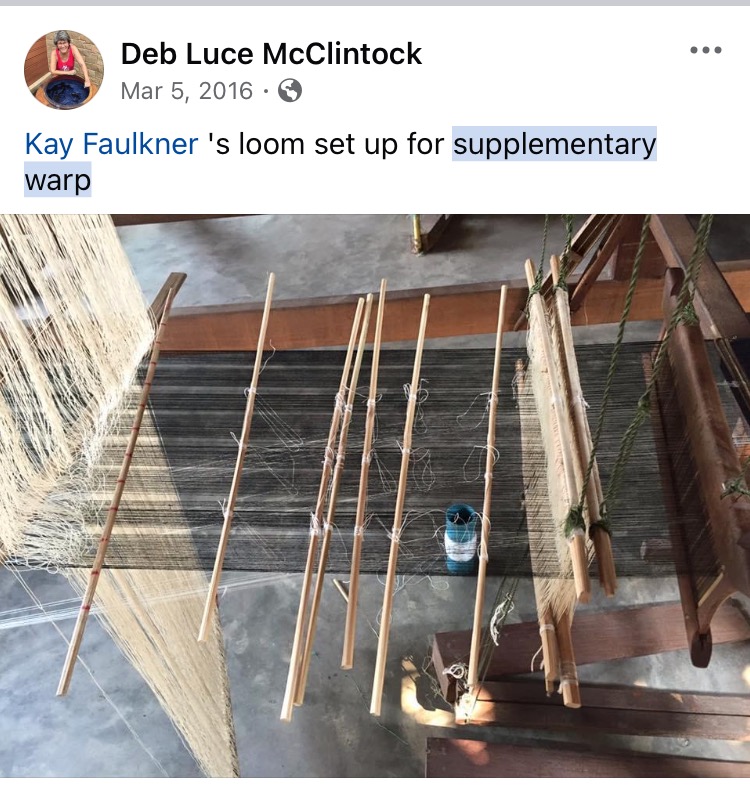

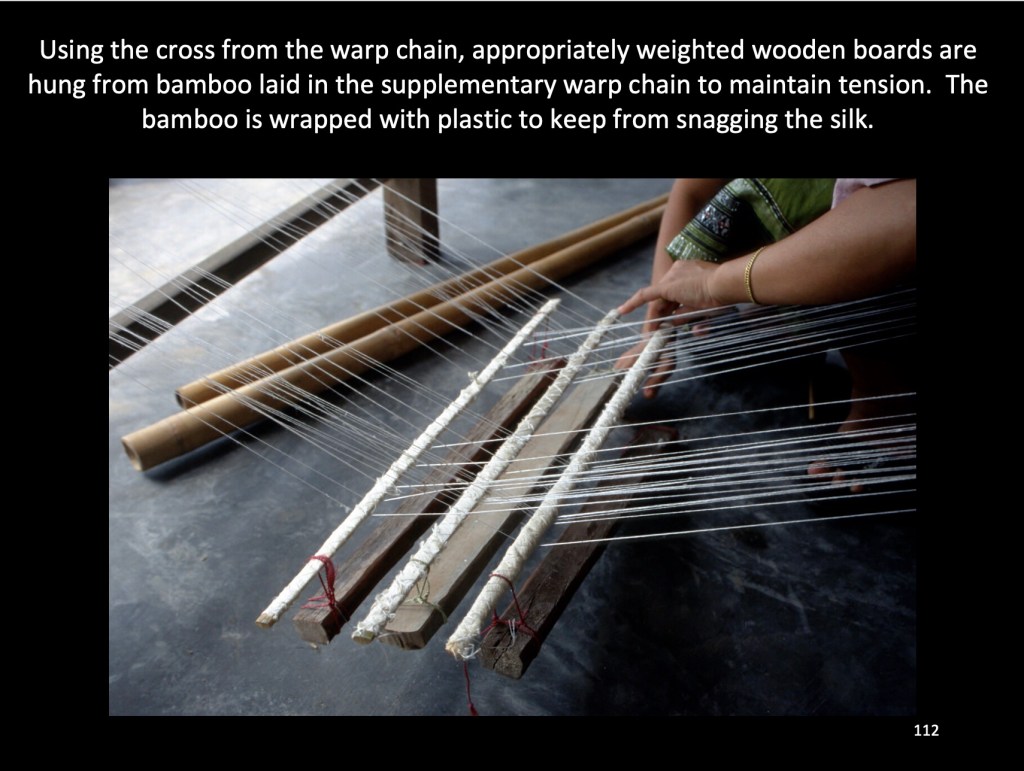

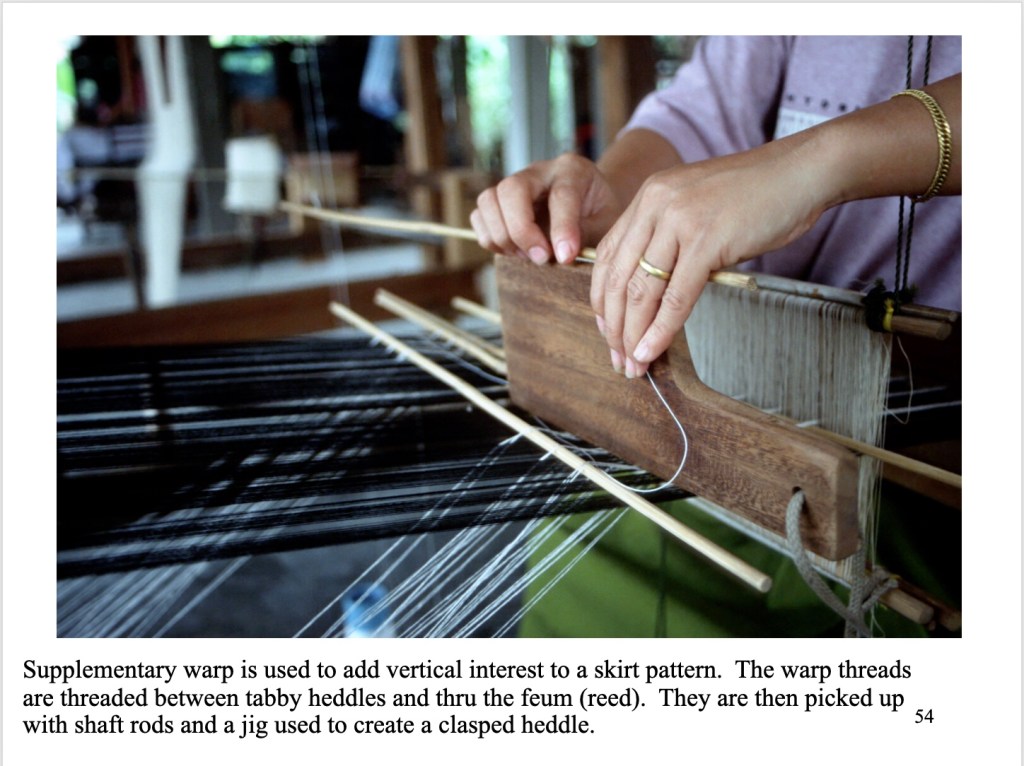

The Supplementary Warp device is also a way to create repetitive pattern thru the cloth. The weaver threads a second warp thru the first warp and picks up the threads and secures them on separate heddles to create the warp pattern. This warp line is weighted separately from the pattern warp and is lifted in tandem with the tie down thread treadling. These photos show those preparations.

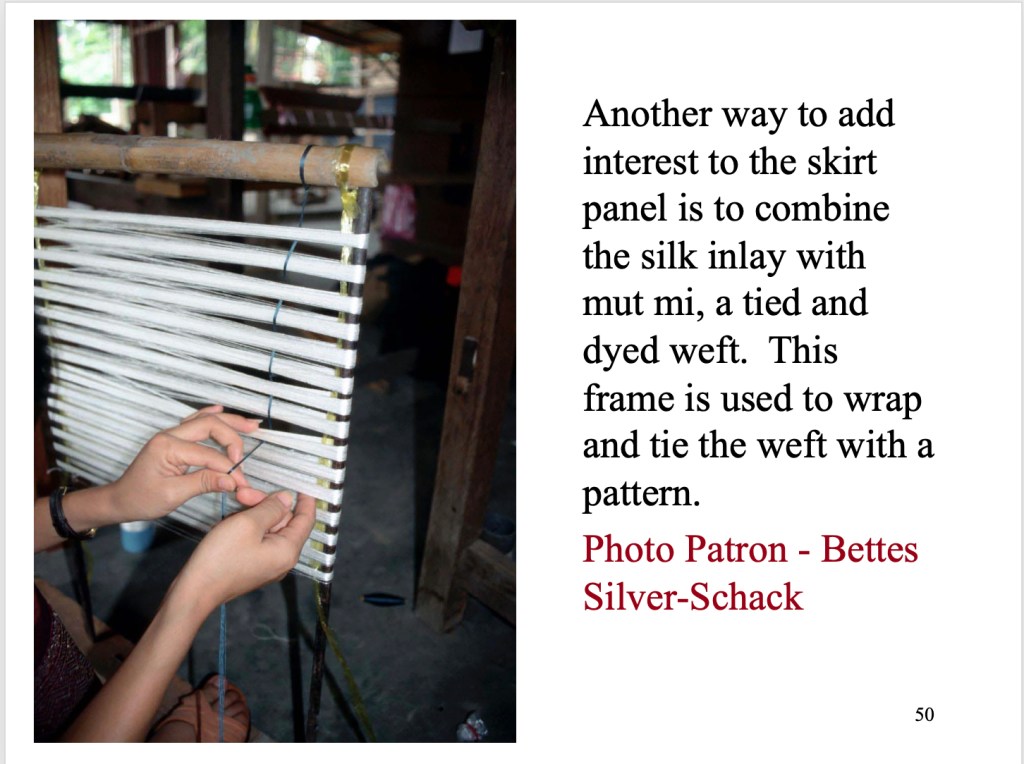

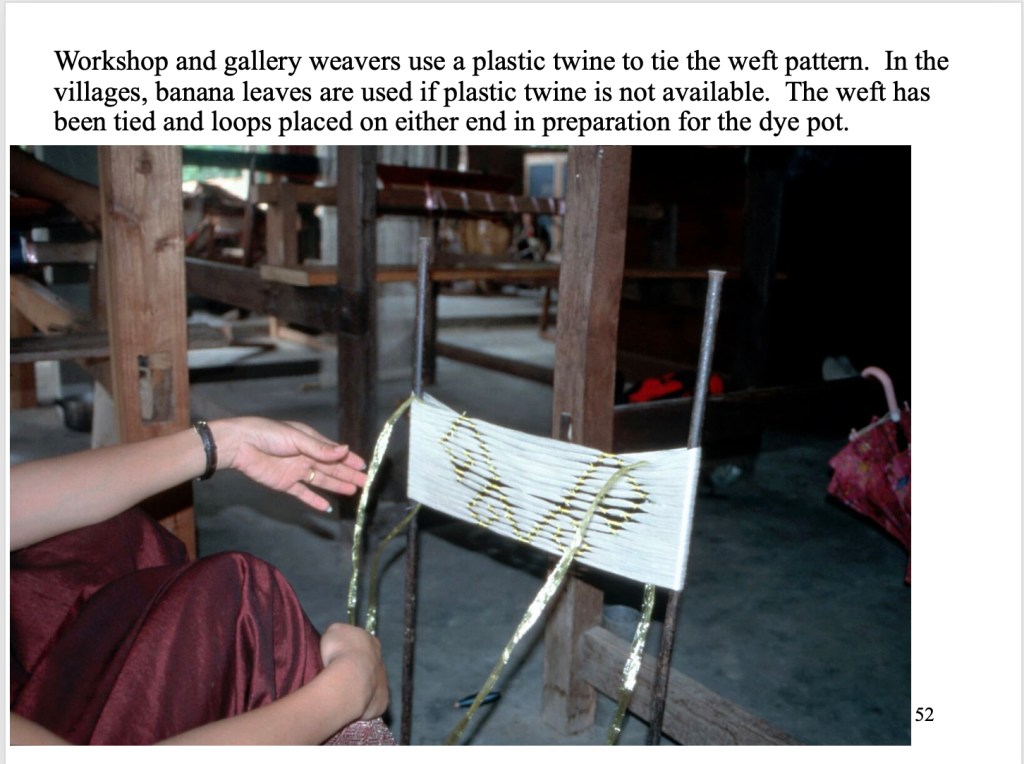

Another process practiced is the careful preparation of mut mi or ikat which is carefully tied, dyed and transferred to shuttles to insert as weft. Below shows the steps in ensuring thread order to bring to the loom.

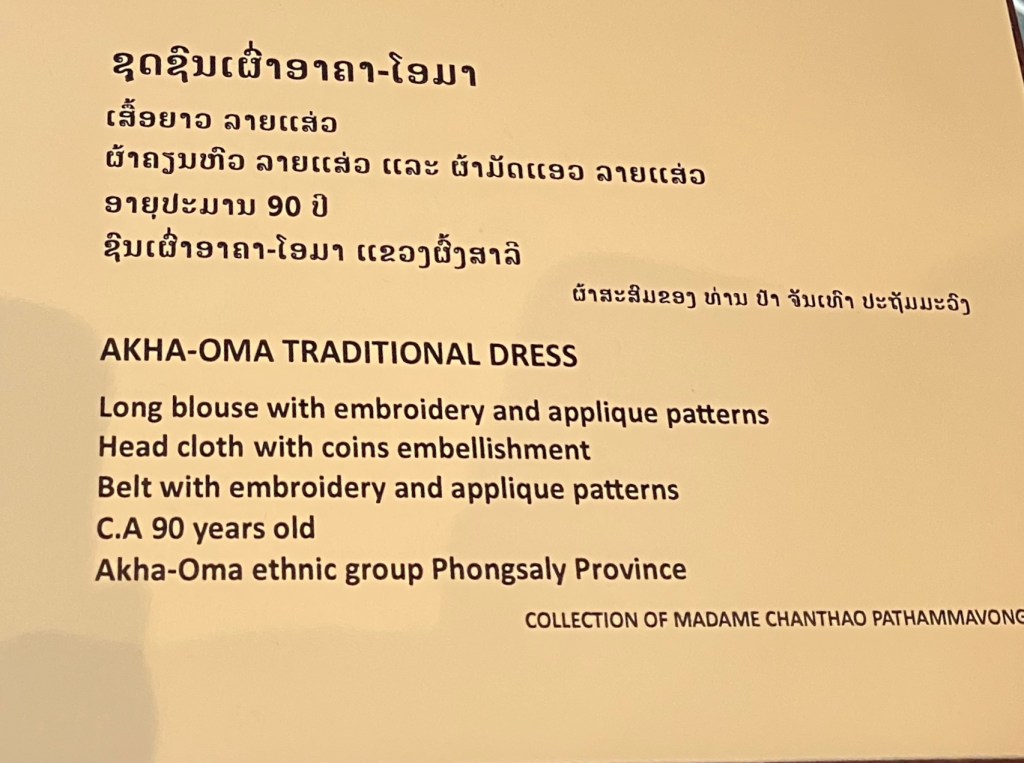

A final process, not pictured, is the silk tapestry technique which is so intricate when rendered in fine silk. You will see some lovely samples of ikat and weft tapestry through these exhibit textiles pictured here. The skill in combining all of these techniques is breathtaking in the final products. All of these process are taught at the Phaeng Mai Gallery by skilled artisans. Finally, the Hmong & Akha-Oma embroidery, batik, appliqué piecing and pleating and backstrap weaving of the south are not illustrated above but are equally Lao and ethnic groups within Laos contribute to the variety of beauty and embellishments reflected in the textiles with their hand skills.

Combining all processes requires equipment and knowledge to combine all the patterns. It is a dance to combine weave, warp and pattern accessories to create these cloths. This delightful woman was winding a warp for 20 skirts along the roadside. We stopped to watch that process and she volunteered to show us her loom. She had additional skirt border shafts to add a special touch to the skirt border.

Through the eyes of the weaver….and the skill at the dye pot and loom.

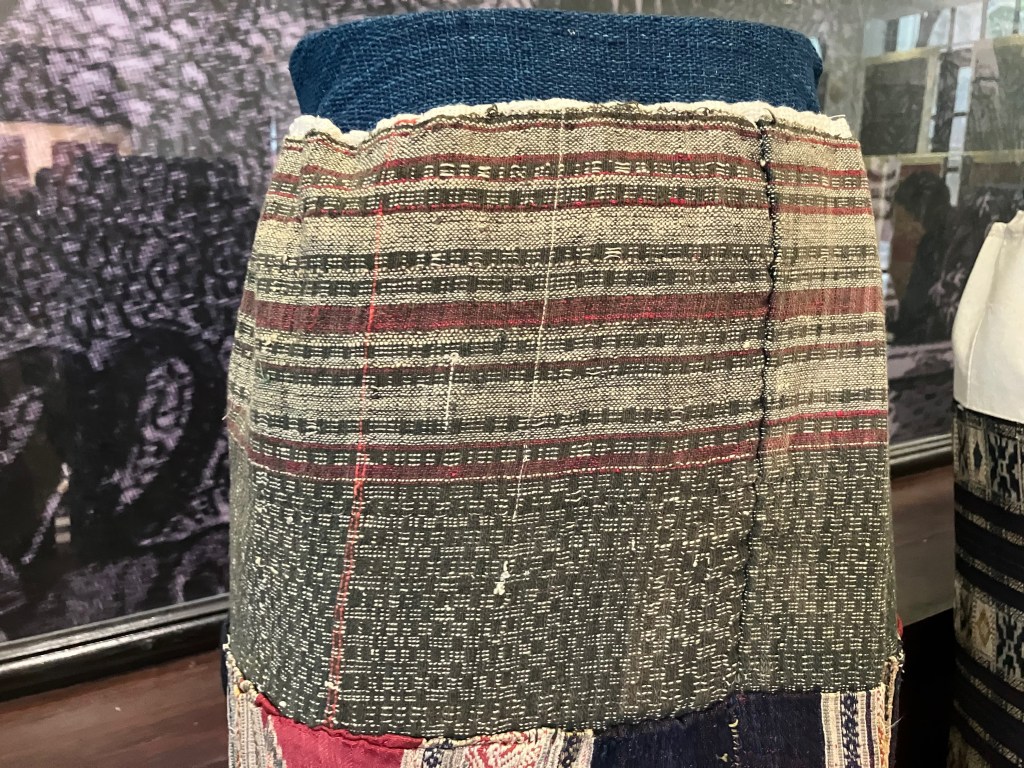

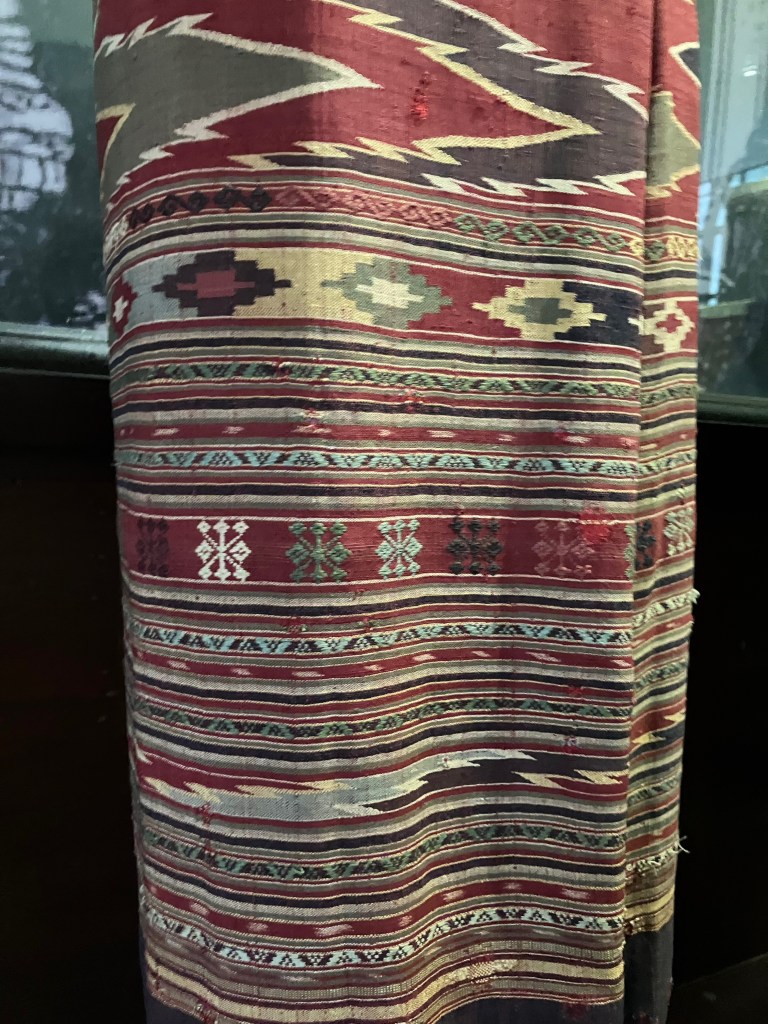

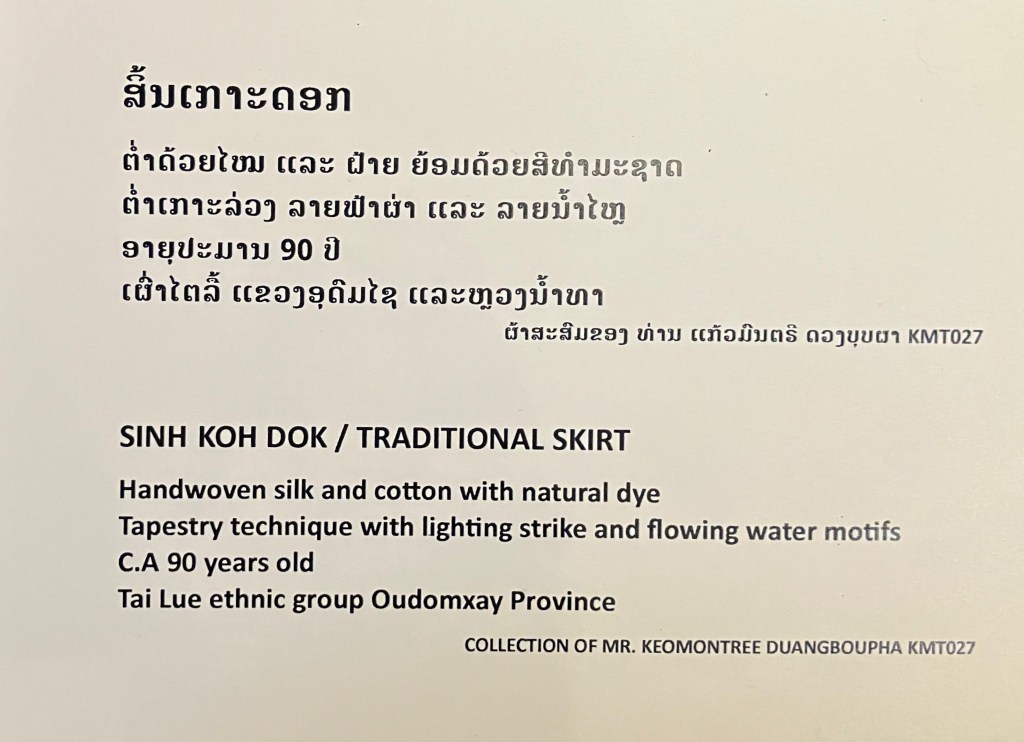

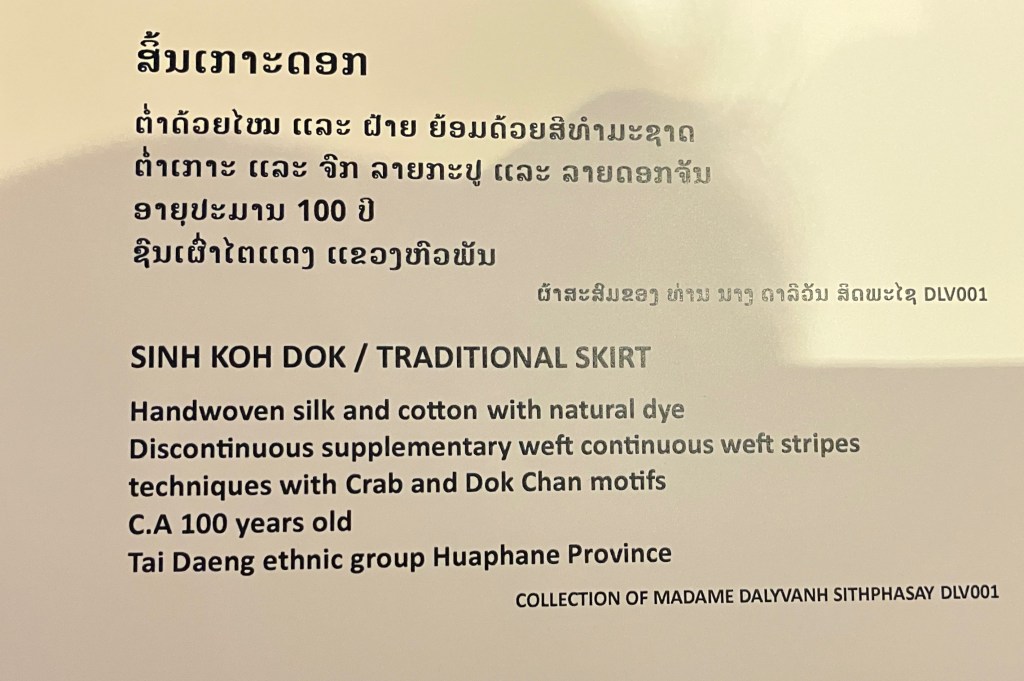

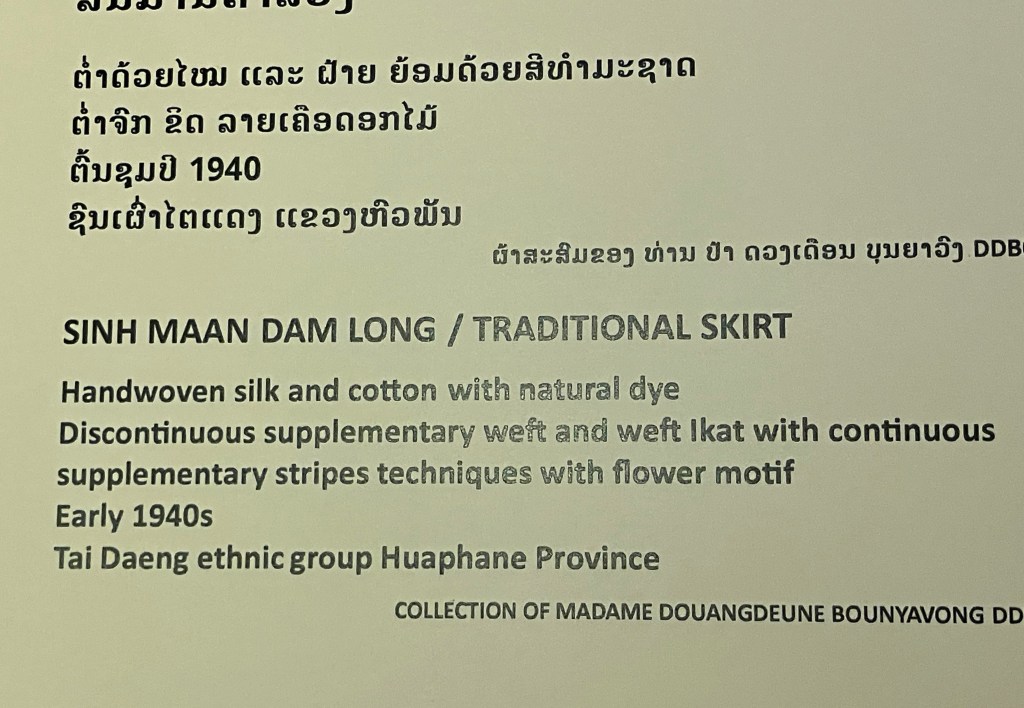

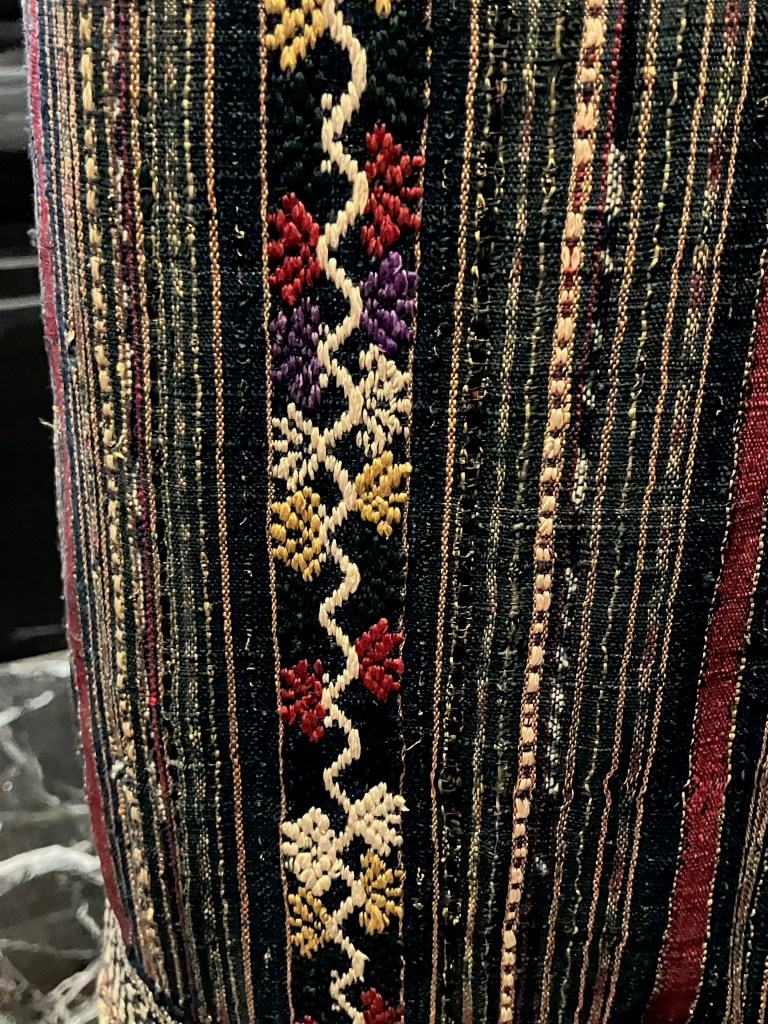

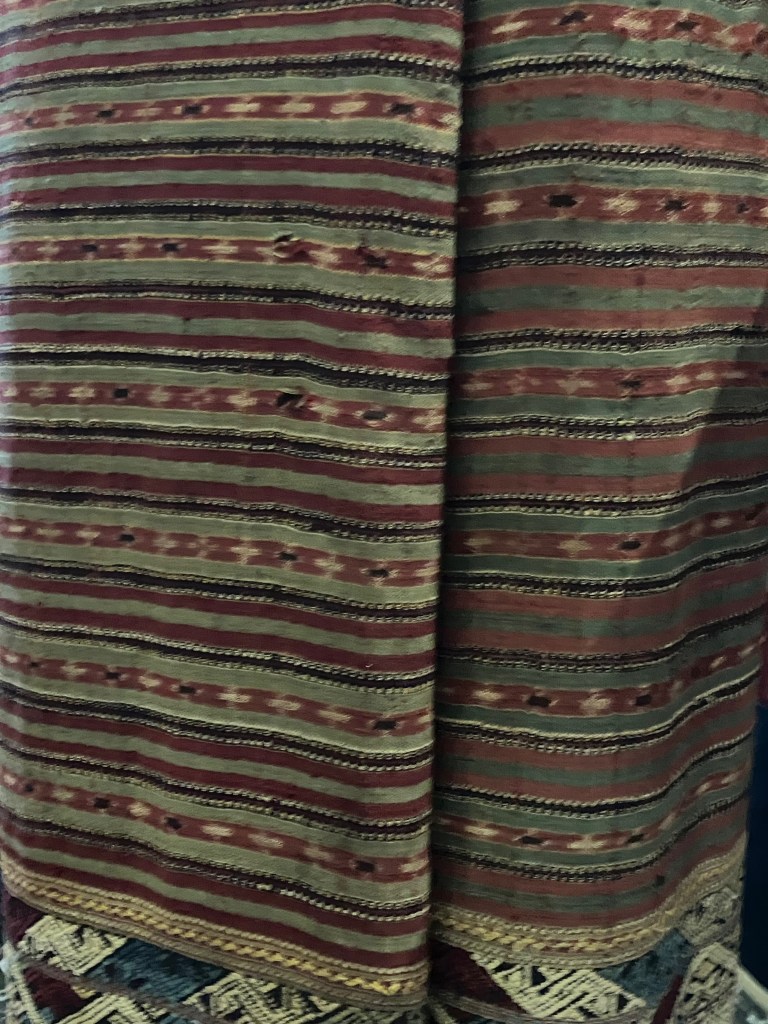

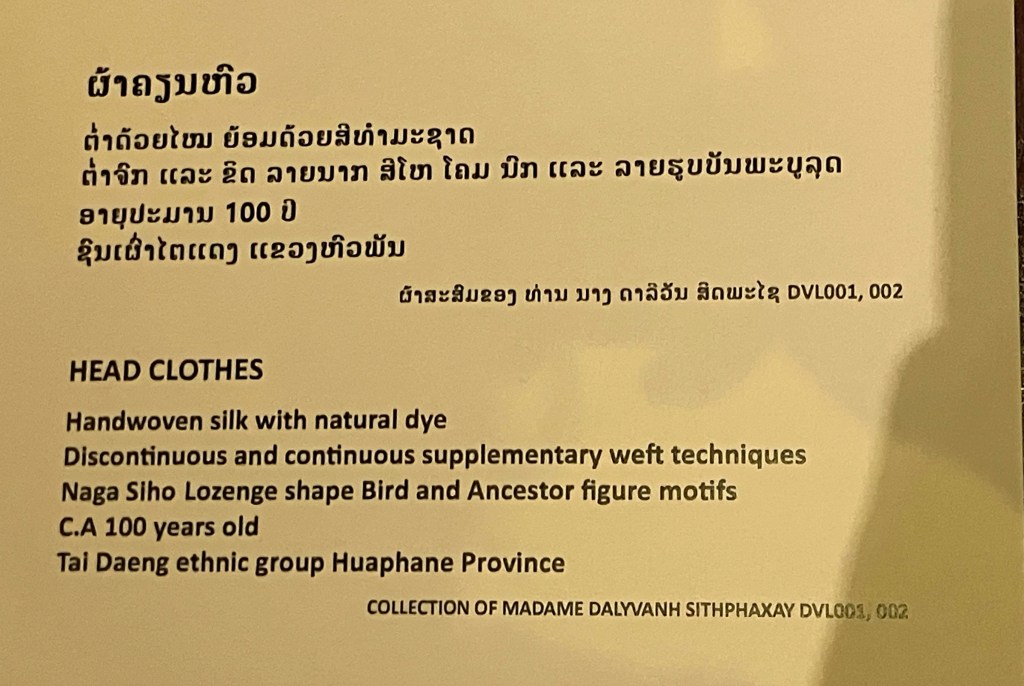

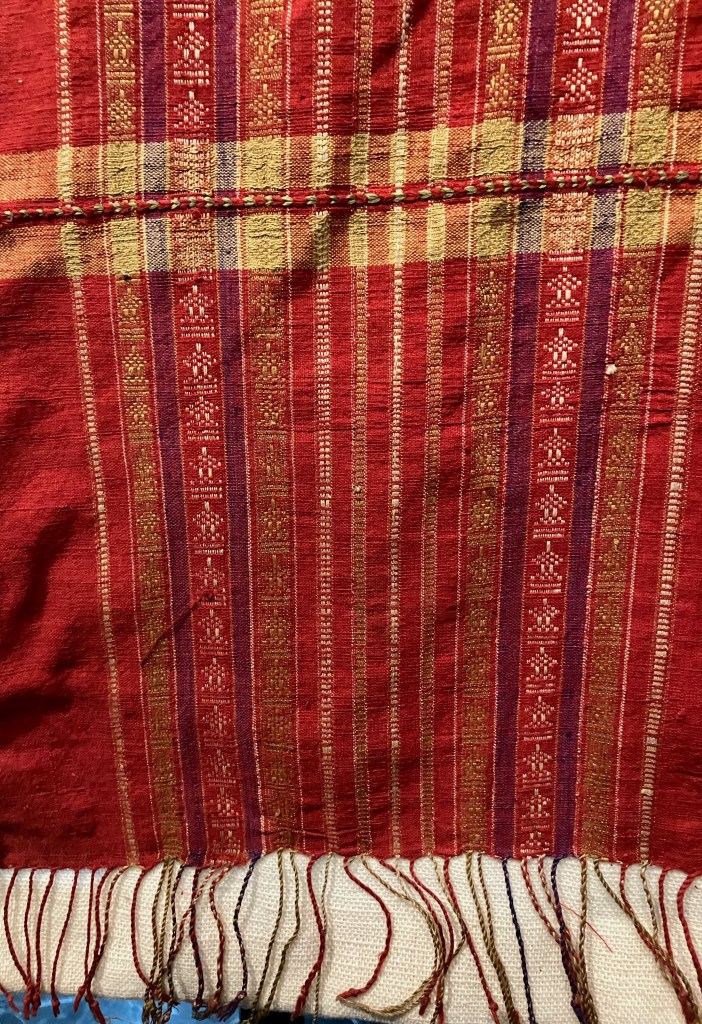

Below are the various textiles I photographed as samples of these beautiful family textiles. They give you an idea of the scope of the collection offered for viewing. Click on each grouping to view the full photo, you can click once more to see a structure close up. I apologize, some labels are not included, we should all hope a catalog will result from this exhibit.

Enjoy. Deb McClintock

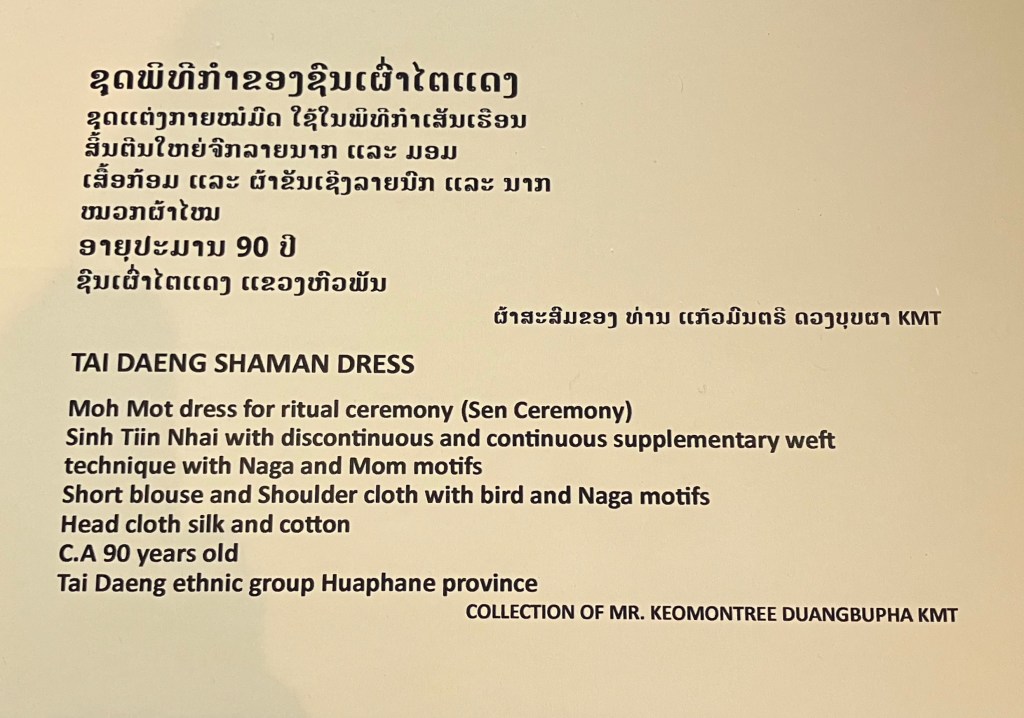

1062-1063 Tai Daeng Shaman Dress note piecing in jacket

1064-1065 Strong example of appliqué & embroidery

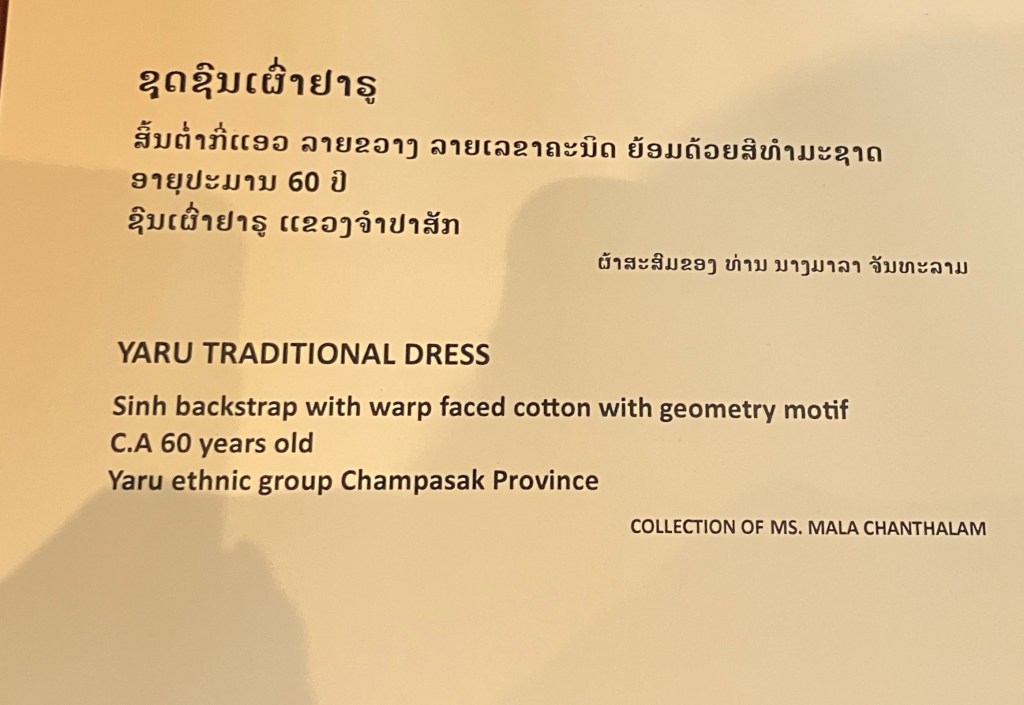

1066-1068 Beautiful example of backstrap texture

1069-1070 Combination of woven ribbons combined with weft stripes in skirt, shaped jacket

1071-1073 note combination of weft striping between discontinues and continuous brocade plus drifting of color within brocade to provide break for eye

1074-1075 Hmong wax resist on hemp with pleated technique & appliqué at hem border insert

1076-1077 lighter texture for southern wear

1078-1083 Fabulous waist border, extensive weft ikat, note weft stripes and brocade for breaks

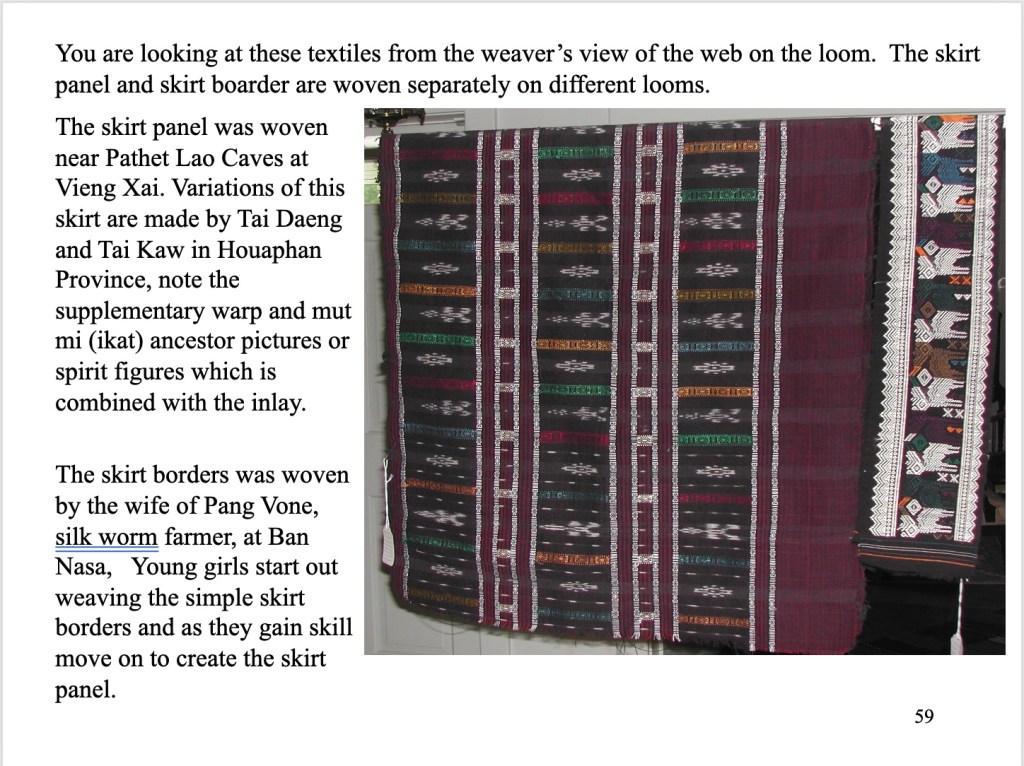

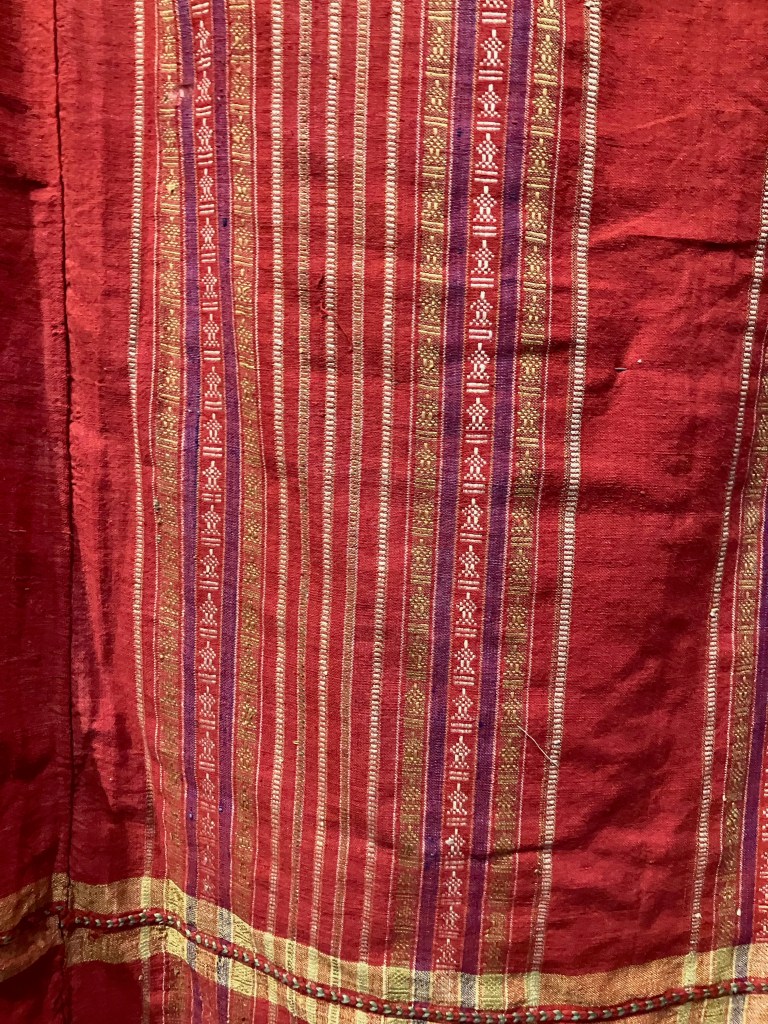

1084-1087 Supplementary warp technique bordering brocade and mut mi

1088-1089 Mastery of natural dye and color design of discontinuous supplementary warp

1090-1092 Mastery of weft fine silk tapestry balanced by discontinuous weft

1146-1149 Another example of stripes and tiny motifs used to frame the discontinuous weft. Look at the detail to see the color switches. The crab motif on the main body shows up in other cultures and carries other names.

1150-1154 This skirt is a master class in color in supplementary stripe placement. I have also noticed that left over mut mi (ikat) is used in their stripes as well.

1155-1158 This skirt shows the use of a complex discontinuous weft border balanced by a use of weft mut mi and stripes

1093-1094 This blanket shows bold use of large motifs bordered by small motif stripes and color weft picks.

1095-1099 Striking command of detail in continuous weft pick up graphic and purposeful joins

1100-1104 Incredible continuous weft pick up offset by discontinuous weft, note color rotation in discontinuous weft

1105-1108 Note separate attachment of multi-color fringe

1112-1115 Below you can see the use of color rotation and the back and forth of the pattern in the long heddles. Drill down in one of the photos to see the simple use of a small motif to create a line divider in different colors. The Lao have a gift of using border lines to isolate and frame larger motifs.

1117-1119 This piece below shows the transition and testing of a pattern for her next cloth in the top right corner. I wish I had captured the join in a closer photograph but a similar join is pictured above in 1095-1099

1123-1126 Great comparison of use of continuous weft and discontinuous weft colors at both ends, the movie shows it best. Note the fringe add on and the use of color to frame border designs.

1127-1132 This piece shows the strength of only using the supplementary warp technique and the simplicity on motif repeats as a whole. Note the twining used in the border. The red is magnificent, I did not capture the label to see if root or lac.

1135-1136 These pieces represent sample cloths used to place the pick up designs properly in relation to each other, providing visuals for the weaver.

1142-1143 The bed cover hanging that provides decoration and supports a mosquito net. This piece shows the impact of smoke in the living area over the years.

Below are the posters accompanying the exhibit plus some of the organizers, we are grateful.

Finally I leave you with a short film prepared by UNESCO and contributed to by several Lao Woman Handicraft leading members, Douangdeaune Boungnavong and Viengkham Nanthavongdouangsy. This 9 minute film prepared by UNESCO gives you the importance of the Naga you see in the textiles and how it integrates into the Lao society.

UNESCO: Representative List of the Intangible Cultural Heritage of Humanity: The Naga is a mythical, serpent-like creature that lives in rivers. Lao people believe that Naga are ancestors that watch over them. Naga motifs are woven by hand using a traditional wooden loom. The motif is woven in silk, silk organza or cotton during the weaving process; it is neither embroidered nor printed. The practice is transmitted informally within families, and in vocational centres, cultural centres and universities. Textiles with the Naga motif are used in daily life, including for newborn blankets and ceremonies. Country(ies): Lao People’s Democratic Republic © Department of Cinema, Ministry of Information, Culture and Tourism

The textiles produced by the weavers on these simple looms require a combination of weaver’s knowledge, body movement and the range of accessories used to control the warp to produce these textile patterns and save the pattern for use again. It is a beautiful dance that creates exquisite textiles. We are grateful to see the work of their hands.

@Deb McClintock Dec 2024

Typically the weaver threads the loom with two warp threads per tooth. The size of the fiber determines how close the bamboo teeth need to be set. The feum would be tailored to fit the density of fiber used. So this fabric will contain a thread count of 1200 ends of silk per the 50-centimeter width of fabric (approx 60 epi). Each weaver has his or her own raw material warp size and product width so the khao tam huuk must be custom made to accommodate the need.

Typically the weaver threads the loom with two warp threads per tooth. The size of the fiber determines how close the bamboo teeth need to be set. The feum would be tailored to fit the density of fiber used. So this fabric will contain a thread count of 1200 ends of silk per the 50-centimeter width of fabric (approx 60 epi). Each weaver has his or her own raw material warp size and product width so the khao tam huuk must be custom made to accommodate the need.

Next he sets up the hawng feum, the jig for tying the teeth to the base sticks of the feum. Hawng represents a room, place or structure; hence the hawng feum is the place the feum is tied.

Next he sets up the hawng feum, the jig for tying the teeth to the base sticks of the feum. Hawng represents a room, place or structure; hence the hawng feum is the place the feum is tied.

The feum maker ties about 3cm of the feum before testing how appropriate the size and spacing of the teeth are for the order specified. If they have to be trimmed down, he takes the work done apart and retrims the teeth on the khaing.

The feum maker ties about 3cm of the feum before testing how appropriate the size and spacing of the teeth are for the order specified. If they have to be trimmed down, he takes the work done apart and retrims the teeth on the khaing.

Once the feum’s bamboo teeth reed is tied and secured Kham Phoune prepares the top and bottom frame. Using a hammer and screwdriver as a chisel he prepares a hole for the left and right hand supports that hold the reed in place in both the top and the bottom of the frame.

Once the feum’s bamboo teeth reed is tied and secured Kham Phoune prepares the top and bottom frame. Using a hammer and screwdriver as a chisel he prepares a hole for the left and right hand supports that hold the reed in place in both the top and the bottom of the frame.

After the teeth are sanded smoothed, the feum is coated with diesel to protect it from insects. Typically the loupe and length of the feum are written on the front of the feum. The feum is now ready to be joined to the khao noy and the khao nyai.

After the teeth are sanded smoothed, the feum is coated with diesel to protect it from insects. Typically the loupe and length of the feum are written on the front of the feum. The feum is now ready to be joined to the khao noy and the khao nyai.

Figure 2

Figure 2

A large wooden jig or pong is brought in to construct the khao nyai. Once again, the jig is cut to the appropriate size as requested by the weaver. The same process is followed as the khao noi for creating the lower half of the clasped loop heddles. See 5 in figure 2. As the loop is created the guide threads are picked up and secured within the khao nyai loop. However, in the khao nya both threads are picked up in the clasped heddle. Hence each clasped heddle stores two of the dummy warps threads that allows the storage of pick up patterns when weaving. Once the top portion of the khao nyai is constructed the stick assembly is flipped over and the bottom portion of the khao nyai is constructed using the same knotting method. See 6 in figure 2.

A large wooden jig or pong is brought in to construct the khao nyai. Once again, the jig is cut to the appropriate size as requested by the weaver. The same process is followed as the khao noi for creating the lower half of the clasped loop heddles. See 5 in figure 2. As the loop is created the guide threads are picked up and secured within the khao nyai loop. However, in the khao nya both threads are picked up in the clasped heddle. Hence each clasped heddle stores two of the dummy warps threads that allows the storage of pick up patterns when weaving. Once the top portion of the khao nyai is constructed the stick assembly is flipped over and the bottom portion of the khao nyai is constructed using the same knotting method. See 6 in figure 2.